Hatch cover seals packing is also called hatch seals watertight door seal or gaskets. They can be made from assorted rubber materials according to the application. Neoprene, EPDM, and natural rubber, are popular for the hatch packing production.

We are able to supply the most common rubber seals on the marked for any application. To suit the cargo you are moving, we can use all sponge rubber types with solid sealing skin.

We also manufacture solid rubber sealing types, as well as sliding rubber profiles. We also produce special hatch packing for naval ships, oil tanks, and chemical tanks. These have specialist characteristics such as fire-resistance and anti-corrosion. Due to our in-house manufacturing, we can produce items according to clients’ drawings or samples with a fast turn around.

CORNER AND END PIECES

We manufacture a range of moulded and fabricated corner and end pieces for most types of rubber seals. Corner and end pieces are critical for tight seals. Our corner and end pieces are to the right type of compression. This is to withstand wear and tear.

Our marine solid rubber packing is suitable for steel hatch covers, used on most new builds. The solid packings have much better properties over sponge packing. Design tooling allows for frequent and steady extrusion. The solid packings tend to have longer life span than traditional sponge packing. Furthermore, we can produce any new designs at lower tooling cost. This includes various nonstandard packing’s according to clients’ request in short and long run quantities.

Please contact us for enquiries relating to non-standard items.

About This Boat Hatch Seal

Hatch Seal is a specially formulated compound rubber that provides a watertight seal and stops leaks. This bulb seal also helps minimize sounds and vibrations that may occur on moving boats.

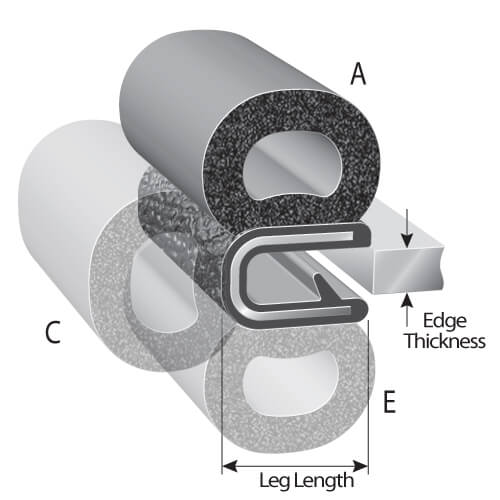

Boat hatch seals are available in two sizes to meet your application needs:

- • 11B – 3/8” bulb

- • 12B – 15/32” bulb

Choose from a variety of edge thicknesses, ranging from 1/6” to 3/32” and two bulb location options. To learn more about our watertight seals, explore the FAQs below.

Why do I need a rubber hatch seal?

Boat interiors can get wet from ocean or lake spray and washing. Keeping that water from draining into storage lockers and other secure spaces is essential to maintaining the lifespan of your marine vehicle and its storage compartments.

Boats can also have an annoying rattling sound that happens when there is space between parts of the hatch. Although most new boats feature watertight marine hatch seals that seal out water and help reduce annoying rattles, many older boats weren’t manufactured with these seals. Or, if they did, the boat hatch seals may have worn out over time.

To keep the boat interiors dry and secure, old or missing gaskets can be replaced with rubber boat hatch gaskets. Specially formulated to promote a watertight seal between the hatches and storage bins in your boat, our boat seals are the perfect solution to keep your storage space protected from water intrusion and damage. Use rubber hatch gaskets to create a water-tight seal for your boat’s:

- • Storage compartments

- • Dry boxes

- • Access doors

- • Floor storage lids

- • Trash units

- • Console doors

Why should I use marine hatch seals?

Intended to replace old gasket material that’s cracked or no longer preventing the hatch from leaking or rattling, the rubber and plastic components of our boat hatch seals are guaranteed to hold up in highly aggressive environments. Ship seal products and boat accessories are a simple way to create a finished edge and protect a wide range of applications from the elements.

More specifically, ship seals line of hatch seals for boats are non-moisture absorbing and resist salt water and oxidation. The closed-cell foam seals out moisture, weather, sound, and fumes. Whether you’re concerned about water damage or are annoyed by constant rattling, our marine hatch seals are the perfect solution.

How do I install watertight hatch seals?

Installing boat seals is easy:

- 1. Clean the edge thoroughly using a solution of one part isopropyl alcohol and one part water with a new, clean rag.

- 2. Cut the boat seal to the desired length for your application, allowing a small amount of extra material.

- 3. Simply press the marine hatch seal onto the edge using a stuffing motion (do not pull) and ensure the edge and metal clip are fully engaged.

What are boat hatch seal compression types?

These bulb seals can be purchased with an optional butyl adhesive sealant to provide extra adhesion and a stronger watertight seal. For information about purchasing rubber hatch seals with butyl adhesive sealants, contact a sales representative.

Although many mistakenly believe that a higher compression rate results in a stronger seal, our boat hatch gaskets are designed and engineered to work best at 25-40% compression of its original height, with 25% being optimum. If you compress it more than that, its life and serviceability will be limited. When building your part, be sure to choose the bulb size that correlates to a 25% compression rate for your application.

Why choose boat seals from Ship Seals?

With easy application, a strong grip, and excellent resistance to ozone, water absorption and sunlight aging, there are plenty of product highlights that set Ship Seals rubber hatch gaskets apart from other options available on the market.

If you’re looking for a durable boat hatch gasket that will protect your marine vehicle from water damage and prevent unnecessary rattling, look no further than Ship Seals. Find an international distributor or contact a sales representative today to purchase a high-quality boat hatch seal.